Call us: 08045476447

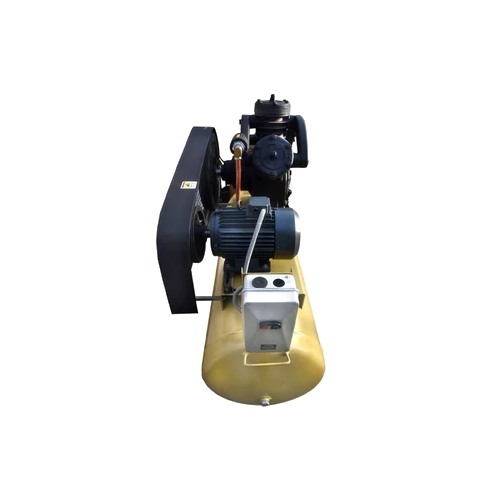

Single Stage Vacuum Air Compressor

Product Details:

- Usage Industrial

- Product Type Single Stage Vacuum Air Compressor

- Condition New

- Material Stainless Steel

- Lubrication Type Lubricated

- Click to View more

Single Stage Vacuum Air Compressor Price And Quantity

- 74000 INR/Unit

- 10 Unit

Single Stage Vacuum Air Compressor Product Specifications

- Lubricated

- Stainless Steel

- Industrial

- New

- Single Stage Vacuum Air Compressor

Single Stage Vacuum Air Compressor Trade Information

- Cash Advance (CA)

- 1000 Unit Per Month

- 10 Days

- All India

Product Description

A single-stage vacuum air compressor is a particular kind of air compressor made for lowering air pressure in a single stage to produce a vacuum or negative pressure. It operates by sucking air into the compressor and compressing it all at once to create a lower pressure than the atmosphere outside.

Single-Stage Vacuum Air Compressor Features and Advantages

Features:

1. Single-Stage Design: The compressor has a straightforward, one-stage design that makes it portable and simple to use.

2. Effective Performance: Applications requiring moderate vacuum levels are suited for single-stage vacuum compressors.

3. Low starting Cost: Single-stage vacuum compressors often have a lower starting cost than multi-stage compressors, making them more affordable.

4. Portable: These compressors are appropriate for a range of applications and are portable due to their small size and low weight.

Benefits:

1. Vacuum Packaging, Material Handling, and Laboratory Use: Single-stage vacuum compressors are appropriate for applications that call for moderate levels of vacuum.

2. Easy Maintenance: The design's simplicity makes maintenance and service comparatively simple, minimising downtime and related expenses.

3. Cost-Effective: Single-stage hoover compressors provide a cost-effective solution for particular hoover needs because of its lower initial cost and ease of maintenance.

4. Versatile Applications: Where moderate vacuum levels are adequate, these compressors are used in a variety of industries, including food processing, electronics, medical, and pharmaceutical.

5. Reduced Noise: Single-stage hoover compressors often make less noise than multi-stage compressors, making them appropriate for workplaces with lower levels of background noise.

The performance of single-stage vacuum compressors may not be adequate for demanding procedures that call for higher vacuum levels, notwithstanding their effectiveness in some applications. Multi-stage vacuum compressors with numerous compression stages can be a better choice in these circumstances.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese